Proof of structural safety is usually derived at by applying mathematical models. But in the case of existing structures or components this theoretical approach has severe limitations. If, for example, the working load is to be increased, building records are missing, the load yield is unclear or the structure is damaged – then only experimental methods get the job done. They reveal the physical reality whilst calculations are always based on assumptions. The experimental proof of structural safety is based on the same officially approved and standardized (sub-)coefficients as the traditional calculations.

Load tests examine the current condition of a structure or component and can therefore:

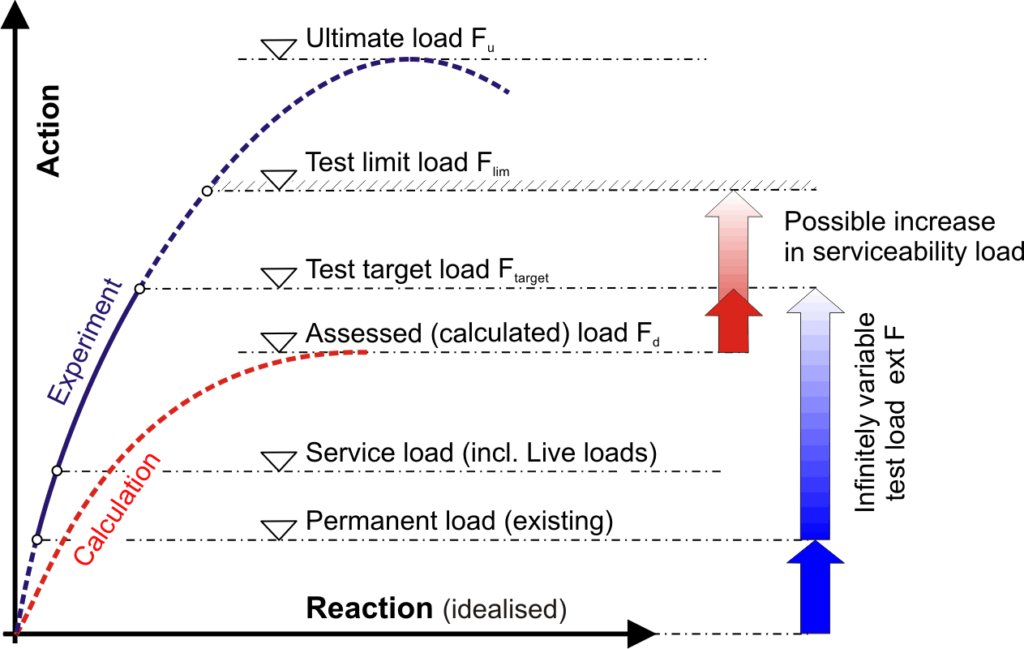

The diagram depicts the general potential of load tests (in simplified form): The measured reactions are smaller than those predicted by calculations and the experimental load can be applied without surpassing any of the relevant threshold values. Therefore we can recommend to use the proven gain ΔQd for an increase of the working load. Our experience shows that the increases amount to 30-50% in most cases. Occasionally they even exceed 100%! This usually happens when the mathematical evaluation was based on assumptions with a large safety buffer.

Load tests are not only used to examine the structural safety. Individual test concepts also allow for the collection of data on deflection, changes in crack widths or strain, so that fitness for purpose can also be proven. The long-term application of an experimental load reveals the long-term bearing characteristics of a structure.